TURNKEY SOLUTIONS FOR INDUSTRIAL MANUFACTURERS

We offer integrated manufacturing services for clients in the industrial sector, delivering fully finished metal parts and assemblies ready for use.

FEATURED PROJECT: INDUSTRIAL CARTS

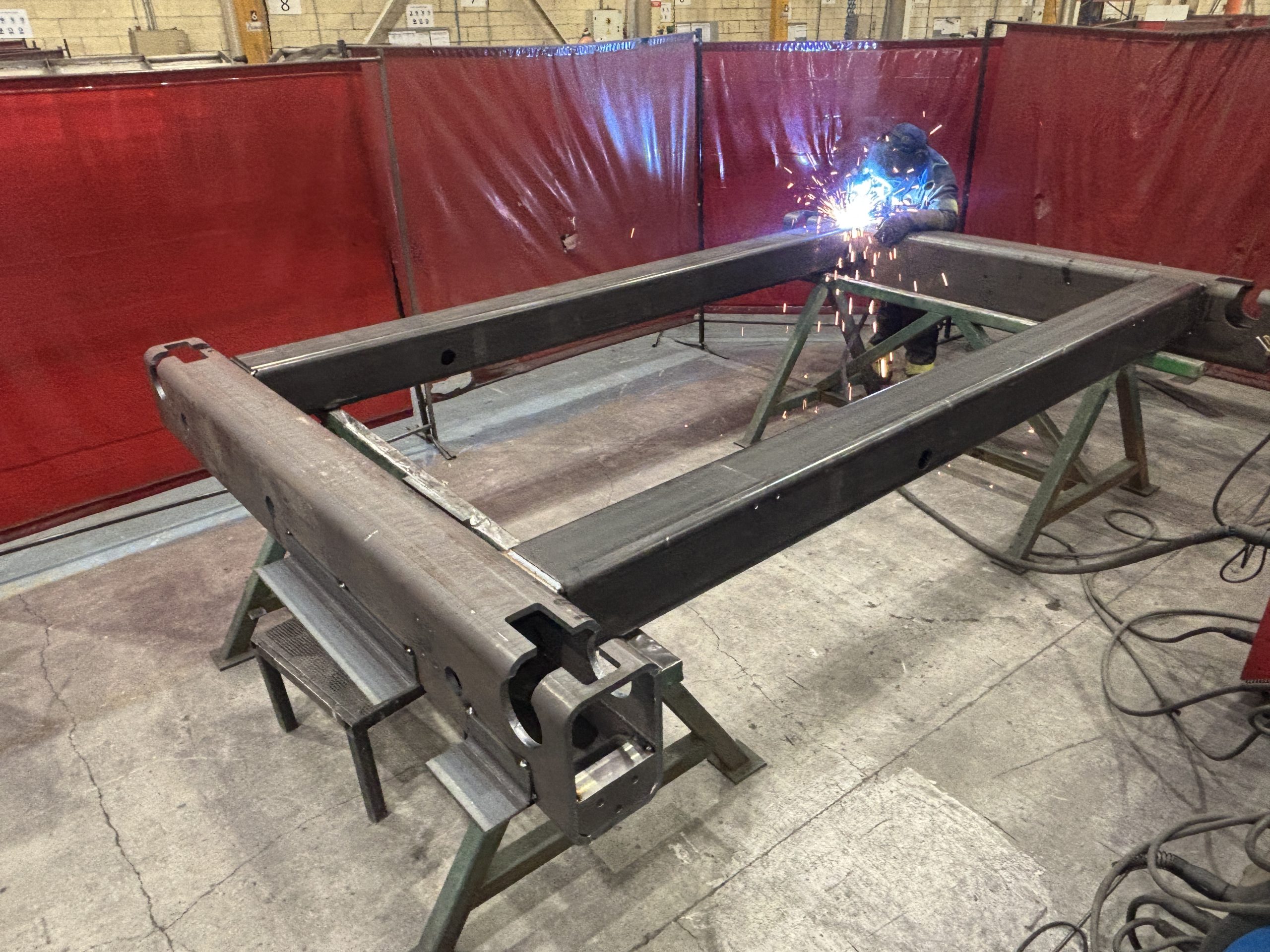

We completed a project for an industrial client involving the comprehensive fabrication of a highly complex mechanical assembly. The entire process was carried out in-house, using large-format components made of S275JR carbon steel.

- • Sheet thicknesses: 2 – 55 mm

- • Sheet dimensions: 3950 x 2300 mm

- • Structural tubes: 300 x 200 x 16 mm

- • Final product dimensions: 3500 x 2500 x 400 mm

Each project brings its own challenges. In this case:

- • We managed the handling of large components and welding sequences, ensuring strict control to prevent deformation. This included edge preparation and weld throats up to 12 mm, requiring precision and control to guarantee structural integrity.

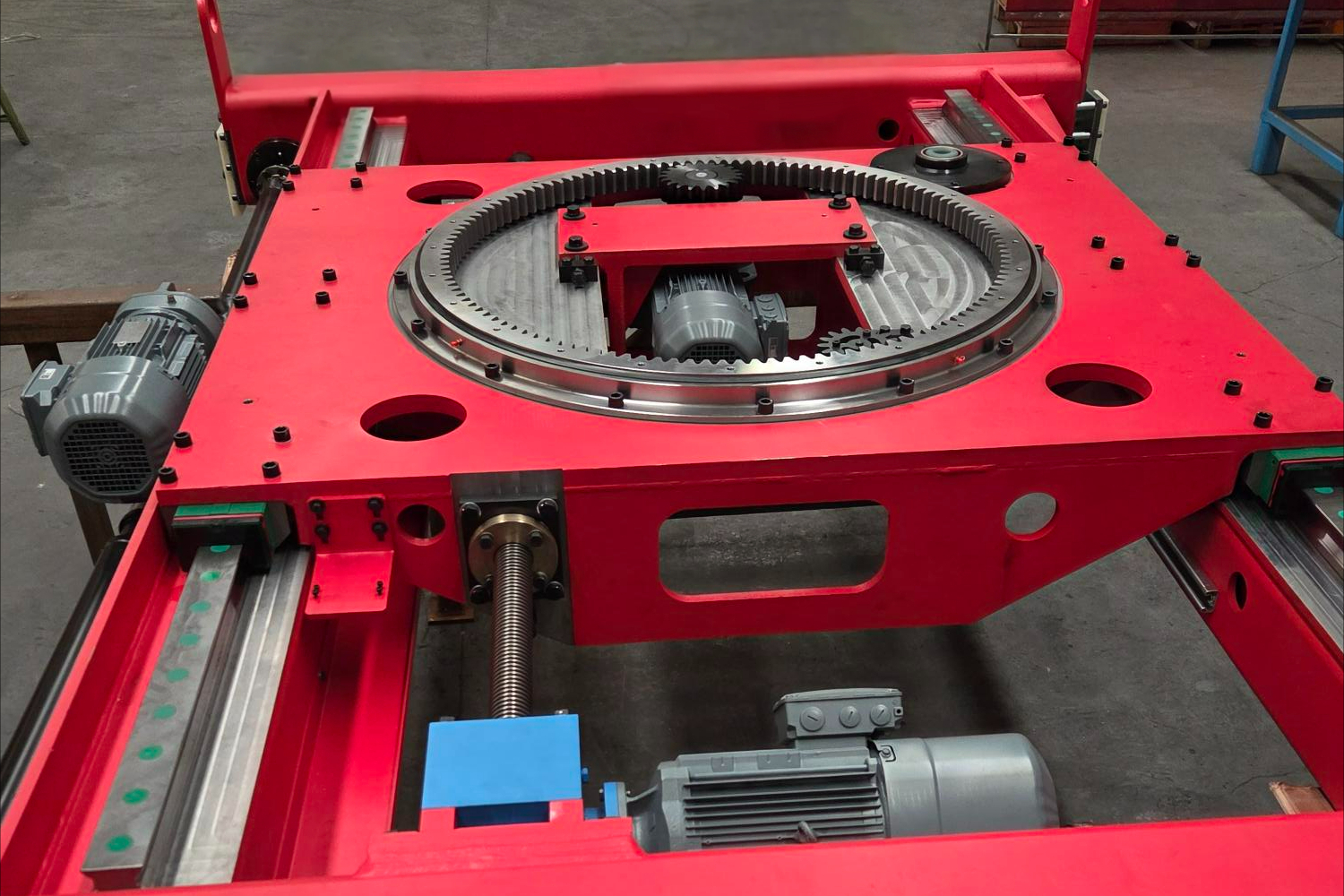

- • We performed complete mechanical assembly of the unit, including torque control and installation of moving parts such as skids, axles, and wheels.

- • We maintained tight tolerances, essential for post-weld machining and ensuring a perfect fit in the final assembly.

We carried out the entire production process—from plan reception to final delivery—entirely in-house, including operations such as metal forming, welding, painting, laser cutting, bending, mechanical assembly, and more.

FINISHED PARTS READY FOR ASSEMBLY

Our full range of in-house services ensures consistent quality, faster delivery times, and greater efficiency for parts and assemblies ready for installation.